Ammonia Printing Machine Futura Three Tube APM F3

Price 40300 INR/ Unit

Ammonia Printing Machine Futura Three Tube APM F3 Specification

- Type

- Triple Tube Ammonia Printing Machine (Blueprinting Machine)

- Material

- CRCA Sheet Metal Structure with Insulation for Sound Proofing, 3x140W Tube Light Sources, Frictionless Gearless DC Drive

- Printing Speed

- 4 meters/minute m/m

- Computerized

- No

- Automatic Grade

- Manual

- Print Direction

- Uni-Directional

- Control System

- Human Machine Interface

- Power

- Power Consumption = 450 Watts, 230V AC 50 c/s Single Phase Watt (w)

- Width

- Maximum Feed Width = 120cm Centimeter (cm)

- Weight (kg)

- Shipping Weight = 54 Kg Kilograms (kg)

- Dimension (L*W*H)

- Product Dimensions = 160cm x 34cm 21cm Centimeter (cm)

Ammonia Printing Machine Futura Three Tube APM F3 Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nhava Sheva

- Supply Ability

- 2500 Units Per Month

- Delivery Time

- 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- 1 Ammonia Printing Machine APM-F3 is shipped in 3 HQ 5-Ply corrugated containers, each protected with EPS, paper edge board and air cushions for maximum safety. The light source and the glass cylinder are shipped in a dismantled state and need to be assembled into the machine body. Installation guide, instruction manual and electrical wiring diagram are included in the package.

- Main Domestic Market

- All India

- Certifications

- Contact us for information regarding our certifications and quality policy.

About Ammonia Printing Machine Futura Three Tube APM F3

Present day digital printing machines may have taken over and replaced the significantly older blueprinting technology, but Ammonia Printing Machine Futura F3 (APM-F3) is still loved by and is the first preference of even some of the most advanced small and medium size drawing offices, drafting stations and R&D tool rooms. It is not just because of the elegant solid state circuitry that controls APM-F3 or the compact structure that beautifully houses the components. It is because of the simple and classic design of Ammonia Printing Machine Futura - F3 that has earned a niche in the drawing office equipment industry 35 years ago, since its inception, and is still at par with any modern printing machine in terms of performance and utility.

Construction:

The machine body is manufactured using prime quality CRCA steel sheets for maximum durability and longevity. A rigid structure combined with a space-saving compact design gives a professional look to the product.

Exposure:

APM-F3 boasts 3 Phillips Holland make 140 Watt Super Actinic light sources and a rotating glass cylinder for exposure. The glass cylinder is driven by an endless conveyor belt which allows users to feed an infinite length of paper and a maximum feed width of 120cm (3 Feet).

Feed Speed Variation:

To ensure a smooth, vibration-free and hassle-free operation, APM-F3 is driven not by friction drives or change gears, but by a 24V variable supply DC motor. Depending upon the details and the quality of the trace required, the exposure time can be very easily adjusted by controlling the speed of the DC motor, with the help of a fine potentiometer. APM-F3 features a maximum feed speed of 4 meters/minutes.

Control Panel:

APM-F3 is fitted with a panel for controlling various operations such as feed speed, feed direction, light on-off and mains power on-off. The control panel is backed by a robust circuit design to ensure long, maintenance-free operation and does not require any cooling device.

Development:

A separate leak-proof static developing chamber is provided along with the machine. The developing chamber is essentially a sheet-metal enclosure with a door fitted with a ball catch latch for easy and fast handling. Suitable provisions for keeping the ammonia roll below the feed platform in a closed roll chamber and to cut the paper on feed platform are also provided.

Power Supply:

Power consumption is nearly 450W and the machine requires a 230V 50 Hertz Single Phase AC Supply. Ammonia printing machine APM-F3 can be operated with any 5 Ampere 3 Pin socket.

Operation:

This machine is very easy to operate. The tracing and ammonia paper are first fed in to the machine over the feed table. They can be adjusted for exact printing speed and mis-feeding of materials can be stopped. The exposed ammonia/diazo paper is then placed in the vertical developing chamber to get the copy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ammonia Printing Machines Category

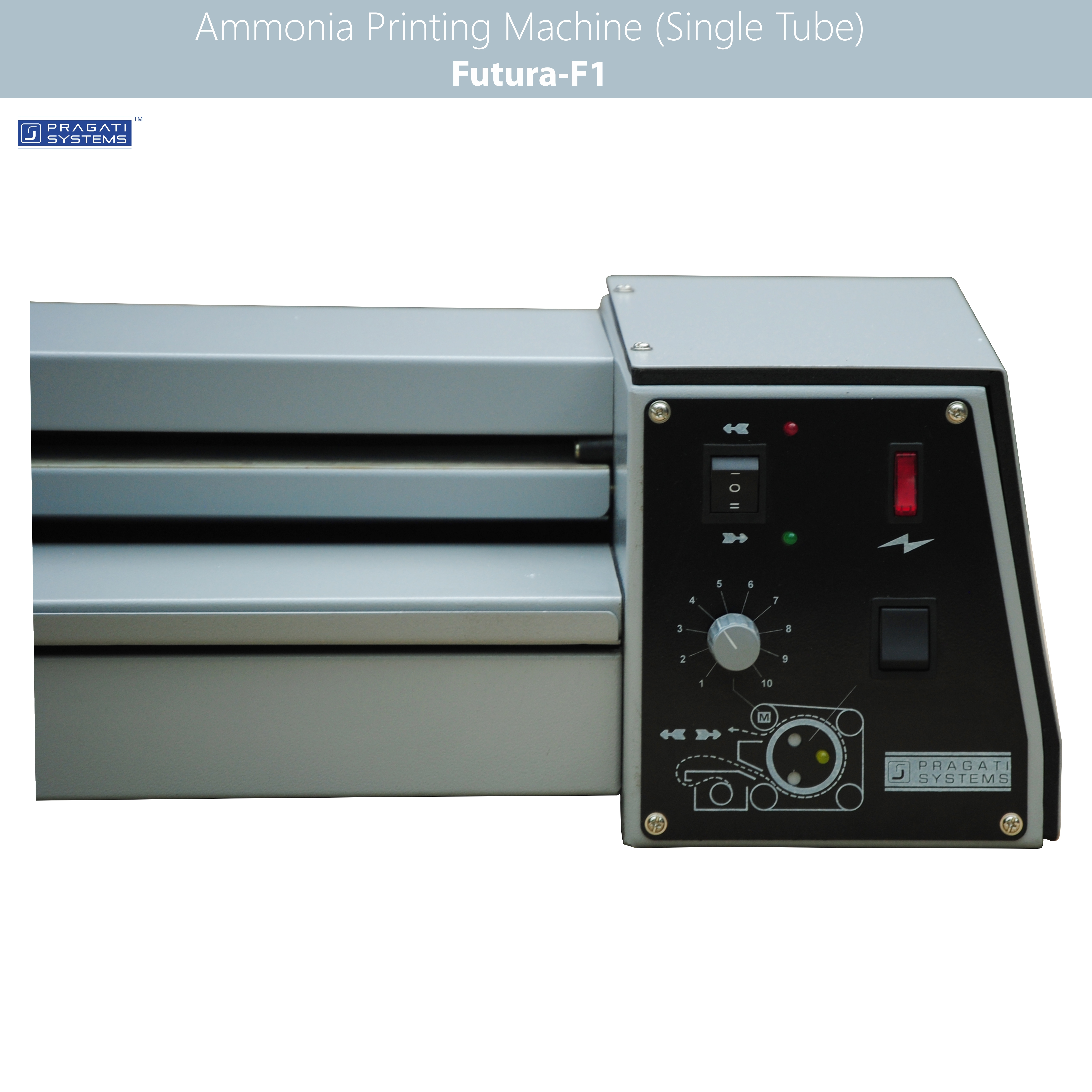

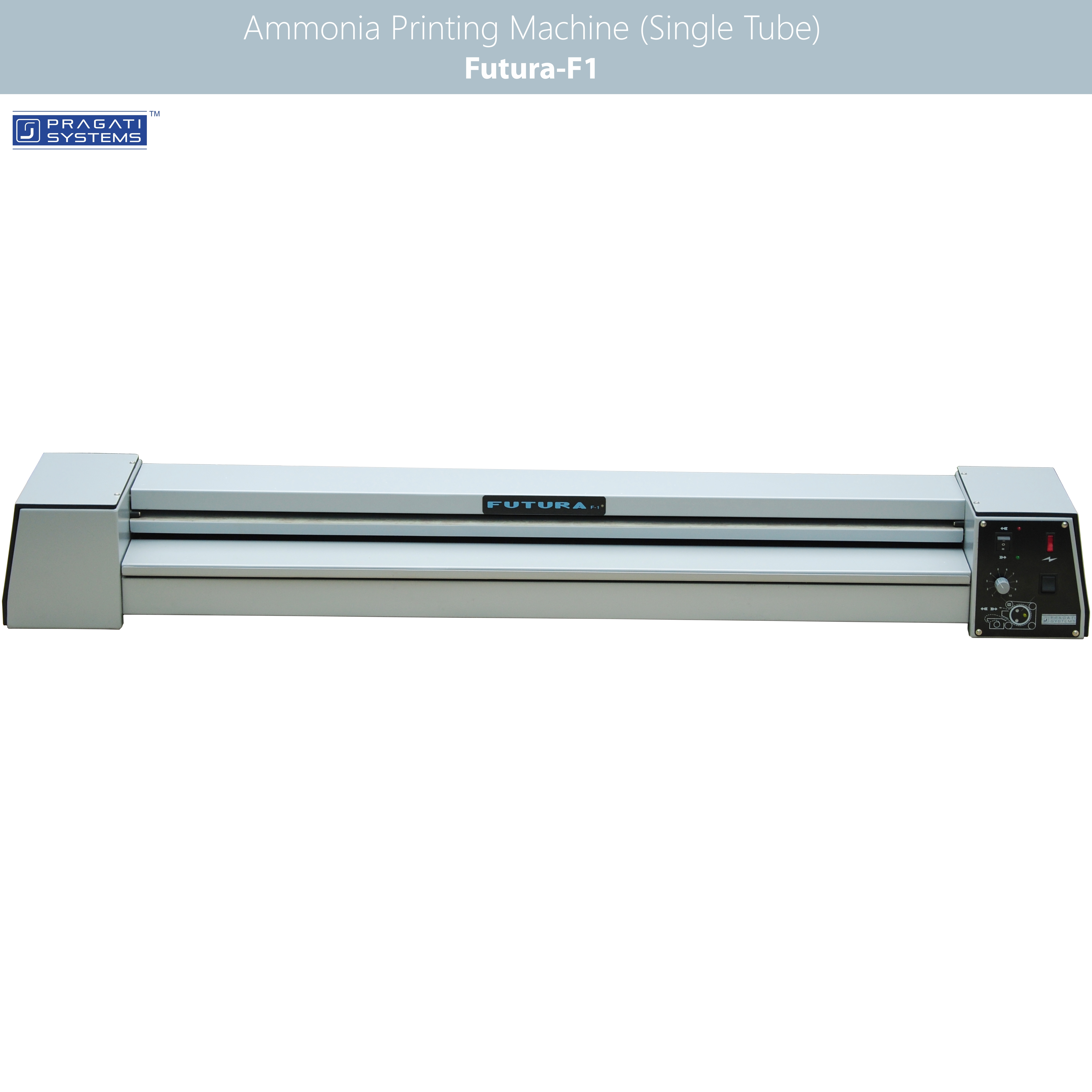

Ammonia Printing Machine Futura Single Tube APM F1

Price 26000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Shipping Weight = 51 Kg Kilograms (kg)

Print Direction : UniDirectional

Material : CRCA Sheet Metal Structure with Insulation for Sound Proofing, 140W Single Tube Light Source, Frictionless Gearless DC Drive

Ink Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free